FIRE PROTECTION

Suppression systems

Clean agent & CO2

Because Silco has an internal design department made up of NICET Level III and Level IV Special Hazard System Engineers and Fire Alarm Engineers who have significant industry experience, we are able to stay current on the latest modern developments. Our aim is to provide a fast return on designs while offering exceptional reports to our valued customers. In order to consult with one of our experts and discover what options are available for your application, contact one of our local Silco offices, or fill out our Contact Us form. Equipped with both the necessary licensing and experience, our skilled technicians possess the knowledge to handle various Special Hazard Suppression systems.

Frequently asked questions

How do I determine if I need a special hazard fire suppression system?

Most often, Special Hazard Suppression Systems find common applications with the presence of high-value assets or hazardous materials. Due to their specific design and purpose, this system effectively mitigates the fire risks associated with these environments. Additionally, our team can conduct a site survey to understand your specific needs and ensure that the right system is provided for your application.

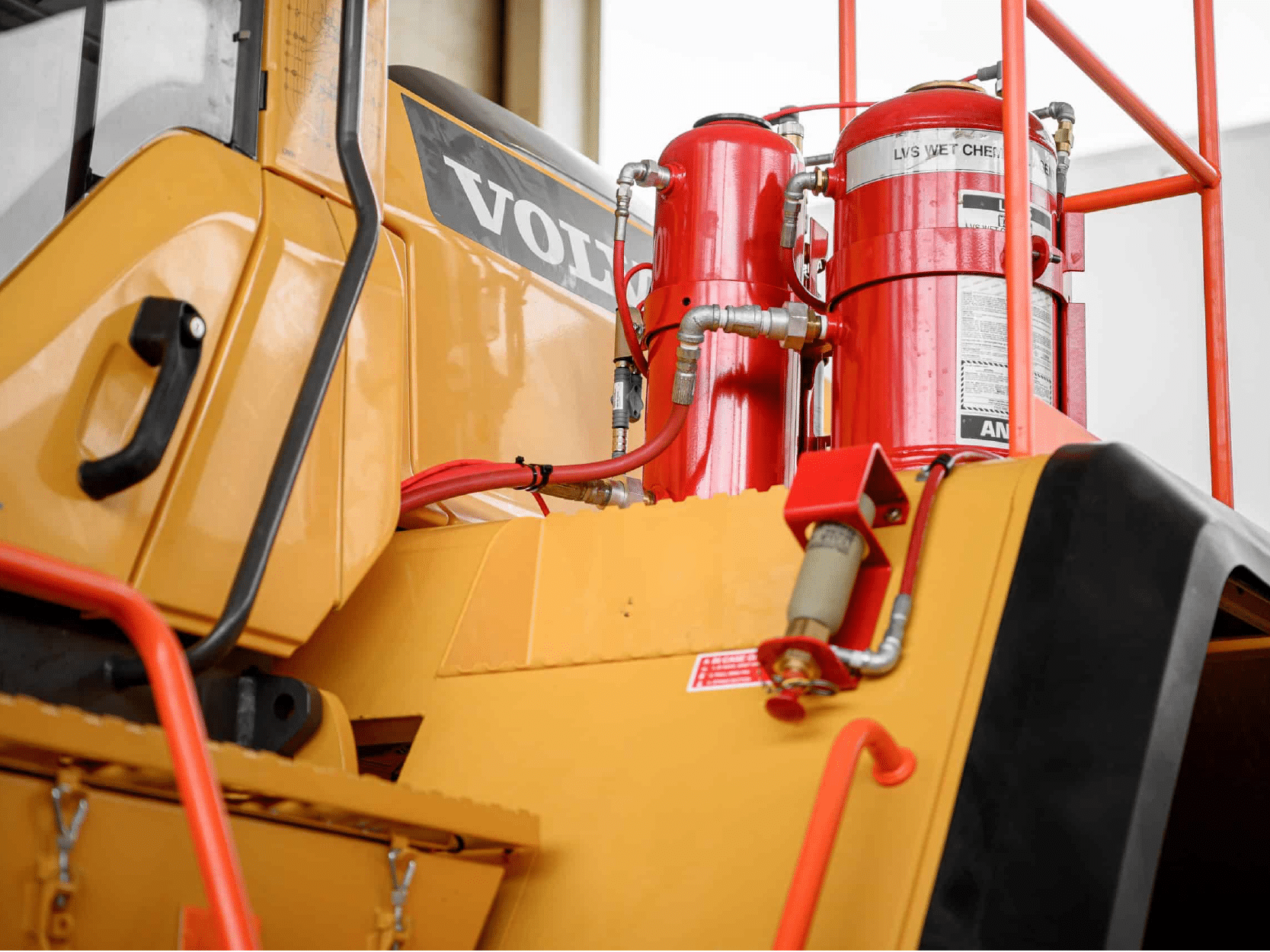

Can I put a fire suppression system on a vehicle?

Certainly, various vehicle types, such as public buses, trains, heavy construction, mining, marine, and racing vehicles, may require suppression systems, and there are multiple options available for each of them.

Does my server room need a fire suppression system?

The value of the data stored on your servers, and the impact on your business on the loss of data in that server room due to a fire, would be a factor whether you need a system or not. Considering the specific risks involved with server rooms, you shouldn’t rely solely on water sprinklers for protection.

If I’m in the room when a clean agent fire suppression system goes off, can I be hurt?

When it comes to clean agent systems, know that they are generally safe to use in the presence of humans. The release of the agent itself does not pose any harm or danger to individuals. However we recommend when alarms sound, to evacuate the area as safely and quickly as possible.

How often does my suppression system need to be inspected?

The frequency may vary depending on various factors, however, as a general rule, we recommend a semi-annual inspection.

Clean agent suppression systems

In addition to their wide-ranging applications, clean agents possess several remarkable traits. Firstly, clean agent systems require no cleanup after discharge, eliminating the post-event efforts significantly. Also, these agents are electrically nonconductive, therefore there is no risk of electrical short circuits or damage. In addition to their safety traits, clean agents are friendly for the environment, making them a responsible choice. Furthermore, they exhibit extremely low toxicity, reducing potential health hazards for occupants. Lastly, these agents are extremely effective, swiftly suppressing fires and minimizing potential damages. Various applications widely deploy Clean Agent Suppression Systems, including server rooms, document storage areas, electronics manufacturing, as well as museums, art galleries, and more.

Carbon dioxide (CO2) suppression systems

Carbon Dioxide (CO2) has an impressive track record as a dependable fire suppression agent for nearly a century, and has also cemented its reputation in the fire protection industry. Also, the effectiveness stems from two key factors: oxygen depletion and cooling. Many Industrial applications utilize CO2 in various applications, such as production lines, quench/dip tanks, industrial fryers, and numerous other applications.

Vehicle suppression systems

Every year, fires destroy industrial equipment worth billions of dollars. However, many companies fail to adequately protect their workers and industrial equipment by implementing proper fire suppression systems. Vehicle Fire Suppression Systems are primarily designed to prioritize the protection of human life, whether it’s an operator situated high atop a loader or children traveling in a school bus. These systems are carefully designed and installed to rapidly and effectively suppress fires, preventing them from reaching the operator or passenger areas.

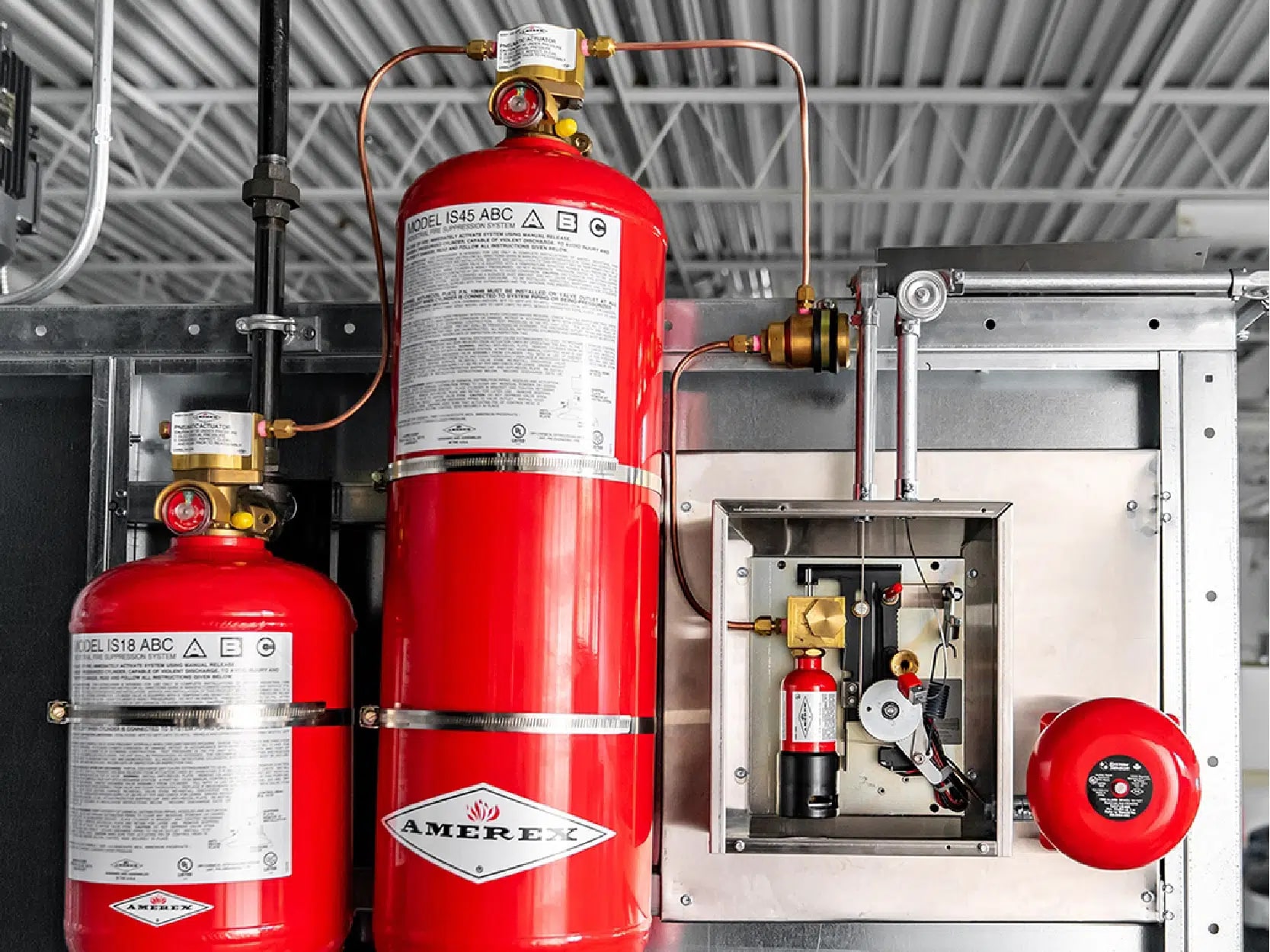

Dry chemical suppression systems

Because Dry Chemical Suppression Systems are available in different arrangements and chemicals for different applications, they have many common applications, some examples are: paint spray booths, gas stations, flammable liquid storage, and various commercial hazards.

Water based suppression systems

These high-performance fire suppression systems are meticulously engineered to safeguard special hazard applications, including combustion turbine enclosures, machinery spaces, generator enclosures, and flammable liquid storage areas. Additionally, they provide proportioning equipment suitable for various system configurations, along with a diverse range of discharge devices tailored to meet specific application requirements.